Transesterification is one of the. Sustainable Aviation Fuel Grand Challenge.

Transesterification An Overview Sciencedirect Topics

Biodiesel a form of ecofriendly fuel has brought a solution to some problems associated with conventional petroleum dieselThis chapter reviews the choice of feedstocks a method of oil extraction and production techniques as important determinants of the success.

. Department of Energy is working with the US. Download Free PDF Download PDF Download Free PDF View PDF. It is derived from vegetable oils like soybean oil or palm oil vegetable waste oils and animal fats by a biochemical process called Transesterification It produces very less or no amount of harmful gases as compared to diesel.

They used the process called transesterification for their production. This method works well if the free fatty acid moisture and phosphorous contents of oilfat are less than 01 percent less than 01 percent and less than 10 ppm respectively. This is the most widely available type of biodiesel in the industry and is often blended with regular marine diesel.

Close Log In. Separation Process Principles- Chemical and Biochemical Operations 3rd Edition. Solomon in Advances in Eco-Fuels for a Sustainable Environment 2019 Abstract.

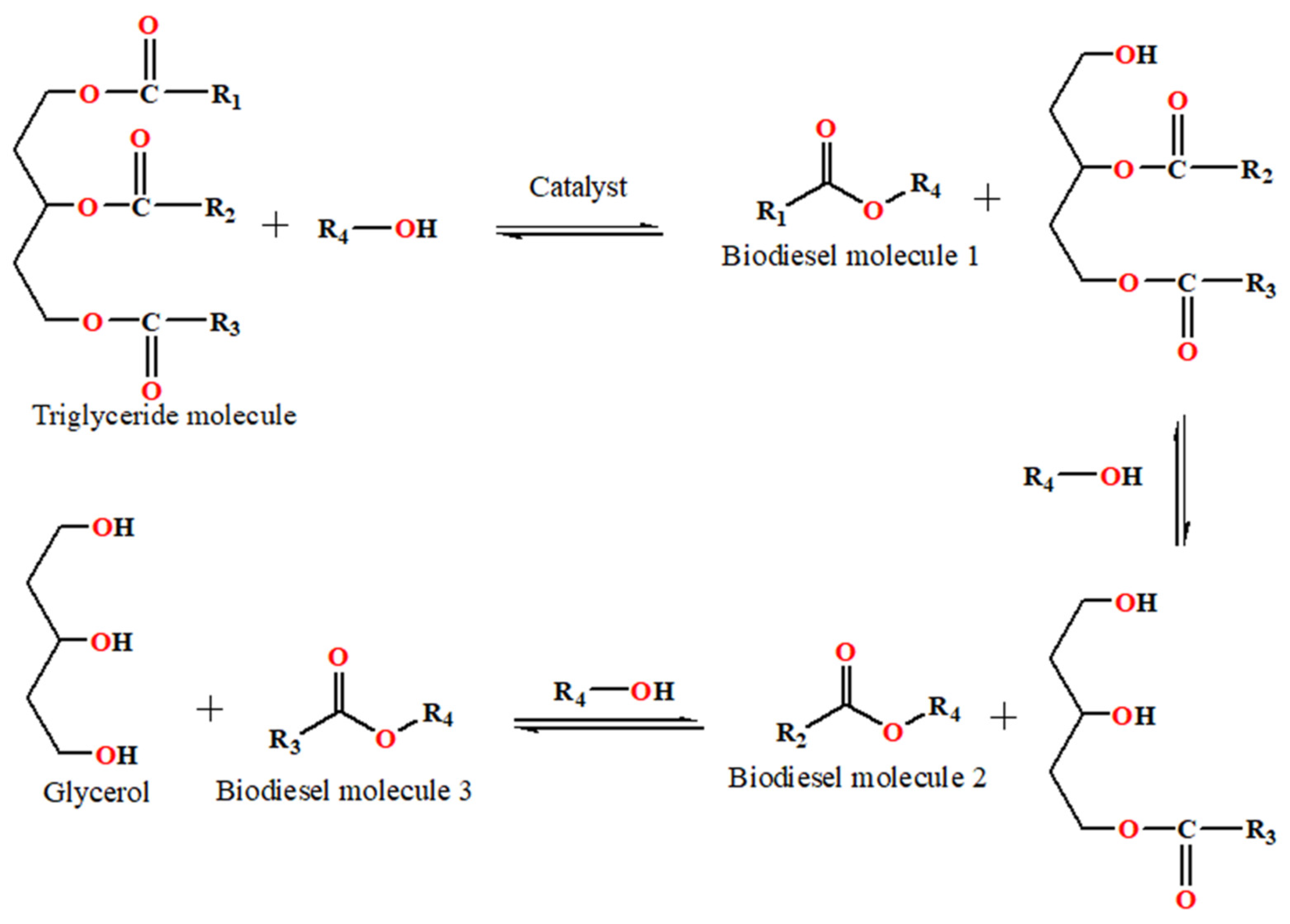

The transesterification reaction is represented by the general equation in Figure 91 a. It can be used as an alternative for the conventional diesel fuel. Biodiesel is another biofuel type which is a renewable source of energy.

Log in with Facebook Log in with Google. The marine fuel specification. Ethanol is the most used because of its low cost however greater.

They are prepared from plant oil and animal fats. Department of Transportation the US. FAME fatty acid methyl aster.

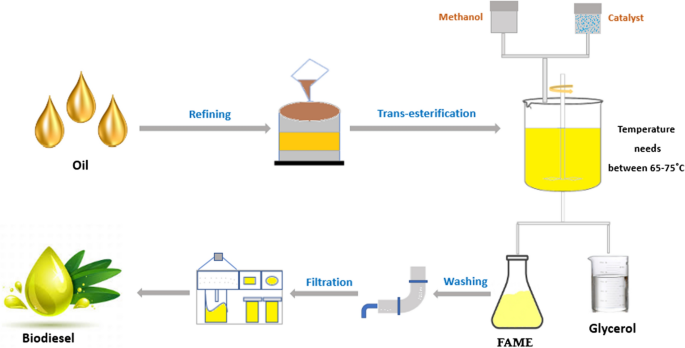

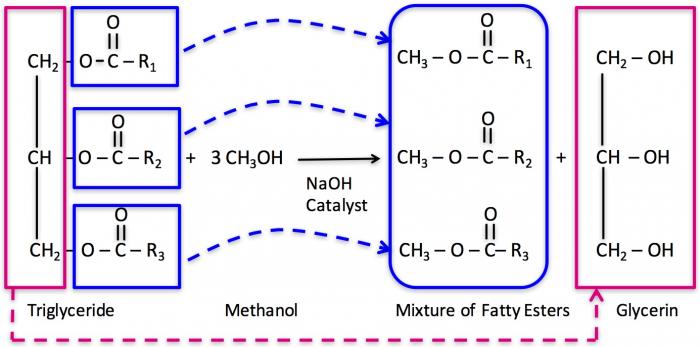

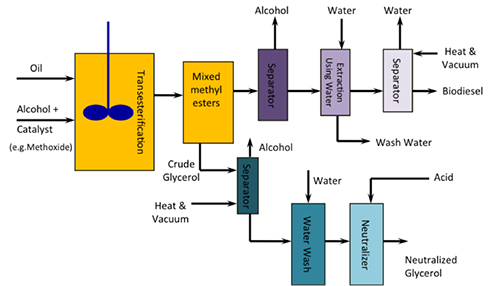

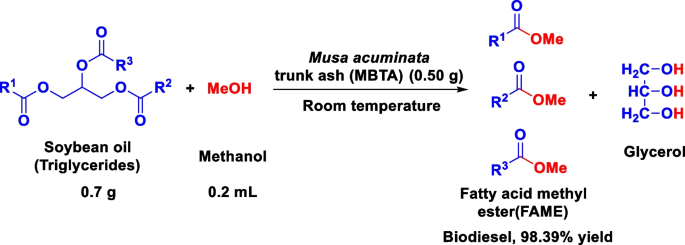

FAME is produced from vegetable oils animal fats or waste cooking oils by transesterification where various oils triglycerides are converted to methyl esters. Production of biodiesel via supercritical methanol transesterification in a tubular reactor. As a method to overcome these challenges microalgal biohydrogen production has become the subject of growing research interest.

Process Economics Program PEP Yearbook is the worlds largest online process economics database with access to 2000 process technologies used to produce 600 chemicals in 6 regionsThe only source for new process analysis PEP Reports and Reviews allow you to uncover the impact of changes in processes feedstocks energy prices and government regulations on. Transesterification is the displacement of alcohol from an ester by another one in a process similar to hydrolysis except that alcohol is used instead of water 18This process has been widely used to reduce the high viscosity of triglycerides. Biodiesel production is the process of producing the biofuel biodiesel through the chemical reactions of transesterification and esterification.

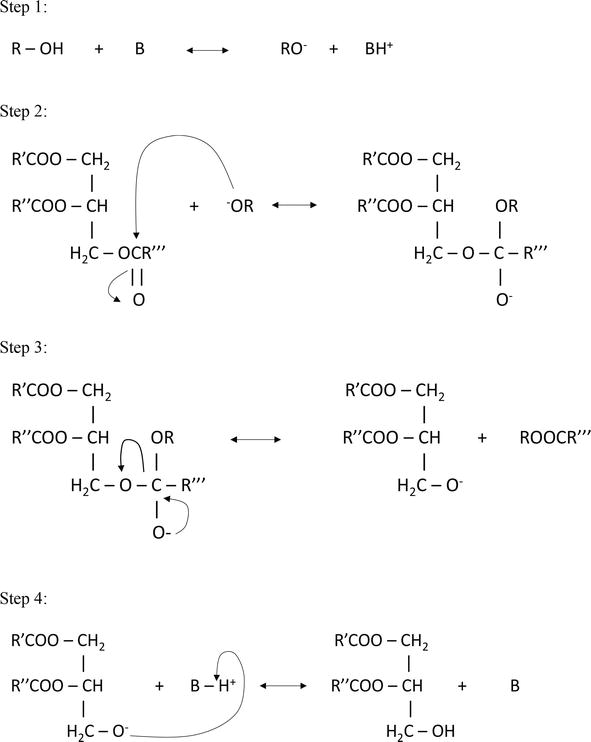

Most of the current biodiesel production operations use base catalysis transesterification. Department of Agriculture and other federal government agencies to develop a comprehensive strategy for scaling up new technologies to produce sustainable aviation fuel SAF on a commercial scale. Add a Spring Pro T76 Dry Wash System to the mix and you can produce a batch of Biodiesel from start to finish in as little as 13 hours.

This involves vegetable or animal fats and oils being reacted with short-chain alcohols typically methanol or ethanolThe alcohols used should be of low molecular weight. Or reset password. Microalgal biohydrogen can be produced through different metabolic routes the economic considerations.

Upgradable Capacity The BioPro 190 Biodiesel Processor is available in a standard model or in a BioPro EX model which adds the revolutionary INCOSEP technology to the processor allowing it to process batches in just under 22 hours. The reaction can also be accomplished with the help of other enzymes particularly lipases one example is the lipase EC3113. The primary sources of vegetable oils are rapeseed palm or soybean.

In organic chemistry transesterification is the process of exchanging the organic group R of an ester with the organic group R of an alcoholThese reactions are often catalyzed by the addition of an acid or base catalyst. Remember me on this computer. Thermophysical and transitive properties of supercritical methanol Energ.

The commercialization of hydrogen as a fuel faces severe technological economic and environmental challenges.

Transesterification An Overview Sciencedirect Topics

Pdf Base Transesterification Process For Biodiesel Fuel Production From Spent Frying Oils

Enzymatic Synthesis Of Biodiesel By Direct Transesterification Of Rapeseed Cake

Role Of Microbial Lipases In Transesterification Process For Biodiesel Production Springerlink

Evc1 Transesterification To Biodiesel

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

Catalysts Free Full Text Nanobiocatalysts For Biodiesel Synthesis Through Transesterification A Review Html

Transesterification An Overview Sciencedirect Topics

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

Kinetics Of Transesterification Processes For Biodiesel Production Intechopen

Enzyme Transesterification Process The Resulting Products Of This Download Scientific Diagram

Widely Used Catalysts In Biodiesel Production A Review Rsc Advances Rsc Publishing Doi 10 1039 D0ra07931f

Transesterification An Overview Sciencedirect Topics

Transesterification Srs Biodieselsrs Biodiesel

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

A Sustainable Protocol For Production Of Biodiesel By Transesterification Of Soybean Oil Using Banana Trunk Ash As A Heterogeneous Catalyst Springerlink